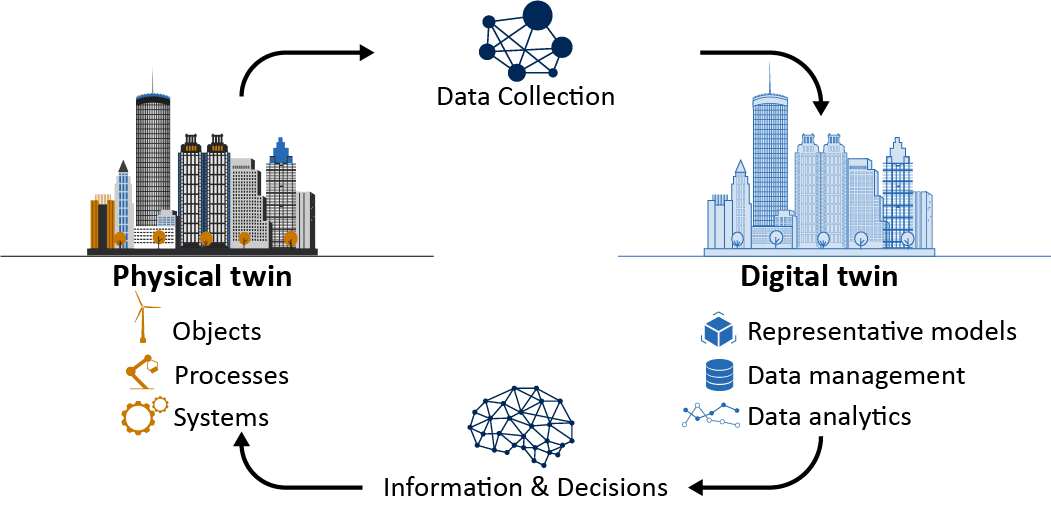

Digital Twins are virtual replicas of physical objects, systems, or processes. They enable real-time monitoring and analysis for improved decision-making.

Digital Twins revolutionize industries by offering precise simulations of physical entities. Companies use them to optimize operations, predict maintenance needs, and enhance product development. This technology bridges the physical and digital worlds, providing valuable insights that drive efficiency and innovation.

Industries such as manufacturing, healthcare, and smart cities benefit from the data-driven approach of Digital Twins. The use of IoT sensors and advanced analytics makes this possible. As the technology evolves, it promises to transform various sectors, leading to smarter, more connected systems. Embracing Digital Twins can lead to significant competitive advantages and operational improvements.

Credit: arrival3d.com

Introduction To Digital Twins

Digital Twins are transforming how we understand and interact with the world. This technology creates virtual models of physical objects. These models help in monitoring and optimizing performance. Digital Twins offer valuable insights and drive innovation.

Concept And Definition

A Digital Twin is a virtual replica of a physical object or system. It uses real-time data to mirror the physical entity. This technology allows for simulations, analysis, and monitoring. Digital Twins provide a comprehensive understanding of objects.

Engineers and scientists use Digital Twins for various applications. They can predict failures and optimize operations. Digital Twins enhance decision-making processes. They create a bridge between the physical and digital worlds.

Historical Background

The concept of Digital Twins dates back to the early 2000s. NASA was one of the pioneers in using this technology. They developed Digital Twins for their space missions. This allowed them to simulate and solve problems remotely.

In recent years, the use of Digital Twins has expanded. Industries like manufacturing, healthcare, and urban planning have adopted this technology. The growth of IoT and AI has fueled the advancement of Digital Twins. These technologies have made Digital Twins more accessible and powerful.

Core Components

Understanding the core components of Digital Twins is key to unlocking their potential. These components work together to create a digital replica of physical assets. Let’s delve into the main components that make Digital Twins so effective.

Data Collection

Data collection is the first step in creating a Digital Twin. This involves gathering data from various sources.

- Sensors and IoT devices

- Historical data from databases

- Real-time data streams

The gathered data is then processed and stored. This data helps in creating a real-time digital copy of the physical asset.

Simulation Models

Simulation models are essential for Digital Twins. They create a virtual environment to test various scenarios.

- Physics-based models

- Data-driven models

- Hybrid models

These models use the collected data to simulate real-world conditions. This helps in predicting outcomes and improving performance.

Integration Platforms

Integration platforms bring all the components together. They ensure seamless communication between physical and digital worlds.

Features of integration platforms:

| Feature | Description |

|---|---|

| Data Integration | Combines data from various sources. |

| Interoperability | Ensures different systems work together. |

| Scalability | Supports growth and expansion. |

Integration platforms make it easier to manage and analyze data. They also enable real-time decision-making.

Applications In Manufacturing

Digital Twins have revolutionized various sectors, especially manufacturing. They allow manufacturers to create virtual models of physical systems. This leads to improved efficiency, reduced costs, and better performance. Below, we explore some of the key applications of Digital Twins in manufacturing.

Process Optimization

Digital Twins assist in fine-tuning manufacturing processes. They simulate real-world operations and identify inefficiencies. This helps in making adjustments that save time and resources.

Factories use Digital Twins for:

- Streamlining assembly lines

- Reducing waste

- Improving product quality

A typical application involves adjusting machine settings. This ensures the optimal speed and quality of production. The result is a more efficient manufacturing process.

Predictive Maintenance

Predictive Maintenance is crucial for minimizing downtime. Digital Twins monitor equipment in real-time. They predict when a machine is likely to fail.

Benefits include:

- Preventing unexpected breakdowns

- Extending equipment lifespan

- Reducing maintenance costs

Manufacturers receive alerts before problems occur. This allows them to schedule maintenance activities proactively.

Digital Twins analyze data from sensors. They provide insights on wear and tear. This information helps in planning timely interventions.

Here is a simple comparison table:

| Traditional Maintenance | Predictive Maintenance |

|---|---|

| Reactive approach | Proactive approach |

| High downtime | Low downtime |

| Higher costs | Lower costs |

Predictive Maintenance ensures machines run smoothly. This leads to consistent production and less disruption.

Credit: constructible.trimble.com

Impact On Healthcare

The impact of Digital Twins on healthcare is transformative. This technology bridges the physical and digital worlds. It enhances patient care, medical training, and the efficiency of healthcare systems.

Personalized Medicine

Digital Twins enable personalized medicine. They create a virtual model of a patient’s body. Doctors can then test treatments on this virtual model. This process ensures the most effective therapy for each patient.

For example, a digital twin of a heart can show how it reacts to different drugs. This helps doctors choose the best medication. It reduces trial and error in treatments.

Here are some benefits of personalized medicine using digital twins:

- Improved accuracy in diagnosis

- Tailored treatment plans

- Reduced side effects

Medical Training

Digital Twins enhance medical training. They provide realistic simulations for students. Trainees can practice procedures on virtual models. This hands-on experience prepares them better for real-life scenarios.

Simulated surgeries on digital twins improve surgical skills. They also help in understanding complex medical conditions.

Benefits of using digital twins in medical training include:

- Safe learning environment

- Enhanced practical skills

- Better understanding of human anatomy

Digital Twins are revolutionizing healthcare. They ensure precise treatments and better-trained medical professionals. This technology is the future of healthcare.

Smart Cities And Infrastructure

Smart Cities leverage Digital Twins to optimize infrastructure and enhance urban living. These virtual replicas model real-world environments, enabling efficient urban planning and resource management.

Urban Planning

Urban planning benefits immensely from Digital Twins. Planners can visualize city layouts in real-time. This technology helps identify potential issues before they arise.

- Simulate traffic flow and reduce congestion.

- Optimize public transportation routes.

- Plan green spaces effectively.

Digital Twins provide data-driven insights. These insights lead to smarter, more sustainable cities.

Resource Management

Resource management is crucial for Smart Cities. Digital Twins offer detailed monitoring of resources.

| Resource | Benefit |

|---|---|

| Water | Track usage and prevent leaks. |

| Energy | Optimize consumption and reduce waste. |

| Waste | Improve collection routes and recycling. |

These technologies ensure efficient use of resources. They minimize environmental impact and reduce costs.

Credit: www.dhl.com

Challenges And Limitations

Digital Twins offer immense potential. Yet, they face several challenges and limitations. These obstacles must be addressed to unlock their full value.

Data Security

Data security is a major concern for Digital Twins. They rely on vast amounts of data. Ensuring the security of this data is crucial. Unauthorized access can lead to significant losses. This includes financial, intellectual property, and reputation damages.

Companies need robust cybersecurity measures. They must protect data from breaches and hacking attempts. Encryption and access controls are vital. Regular security audits are also necessary.

Technical Barriers

Technical barriers often hinder the adoption of Digital Twins. Integration with existing systems is challenging. Compatibility issues arise frequently.

Developing and maintaining Digital Twins is complex. It requires specialized skills and expertise. Not all organizations have the required technical know-how. This creates a dependency on third-party vendors.

The cost of implementation is also high. Small and medium-sized enterprises struggle with this. They might lack the necessary financial resources.

| Challenge | Impact |

|---|---|

| Data Security | Potential financial and reputation damage |

| Technical Barriers | High costs and complexity |

Future Trends

The concept of Digital Twins is evolving rapidly. The future trends in this space are promising and innovative. Let’s explore some of these trends.

Ai Integration

Artificial Intelligence (AI) will play a crucial role in Digital Twins. AI can analyze vast amounts of data. This analysis helps in making better decisions. AI can also predict future issues. This predictive capability is vital for maintenance and improvements.

Here are some key areas where AI will integrate with Digital Twins:

- Predictive Maintenance: Identifying potential failures before they occur.

- Optimization: Enhancing efficiency in processes and operations.

- Automation: Reducing the need for human intervention.

- Real-Time Insights: Providing up-to-the-minute data analysis.

Scalability

Scalability is another important trend. As technology advances, Digital Twins will need to scale effectively. This means they will handle more data and more complex systems.

Consider these aspects of scalability:

| Aspect | Description |

|---|---|

| Data Handling | Managing increasing volumes of data efficiently. |

| System Complexity | Accommodating more intricate and interconnected systems. |

| Integration Capability | Seamlessly integrating with other technologies and platforms. |

Cloud computing will aid in scalability. Cloud platforms offer the required infrastructure. This ensures that Digital Twins can grow without limitations. Additionally, edge computing will play a significant role. It will help in processing data closer to the source. This reduces latency and improves performance.

Case Studies

Digital twins have revolutionized various industries. They enable real-time simulation and analysis. This section explores compelling case studies. These illustrate the power of digital twins in action.

Success Stories

Several companies have achieved remarkable outcomes using digital twins. Here are a few noteworthy examples:

- General Electric (GE):

- GE uses digital twins to monitor jet engines.

- This enhances performance and reduces downtime.

- Siemens:

- Siemens employs digital twins in manufacturing.

- They have improved efficiency and reduced waste.

- NASA:

- NASA uses digital twins for space missions.

- They simulate conditions and plan missions safely.

Lessons Learned

From these success stories, valuable lessons emerge. Here are key takeaways:

- Data Integration:

- Combining data from multiple sources enhances accuracy.

- Scalability:

- Scalable solutions adapt to growing needs.

- Predictive Maintenance:

- Predictive maintenance prevents costly failures.

These lessons learned guide future digital twin projects. They ensure success and innovation.

Frequently Asked Questions

What Is A Real Example Of A Digital Twin?

A real example of a digital twin is General Electric’s digital wind farm. It uses digital twins of turbines for performance optimization.

What Are The Three Types Of Digital Twins?

The three types of digital twins are: 1. **Product Digital Twins:** Represent individual products throughout their lifecycle. 2. **Process Digital Twins:** Simulate manufacturing and operational processes. 3. **System Digital Twins:** Model entire systems or ecosystems for performance and efficiency analysis.

What Are Human Digital Twins?

Human digital twins are virtual replicas of individuals. They simulate physical and psychological characteristics for healthcare, research, and personalized experiences.

What Is The Difference Between Virtual Twins And Digital Twins?

Virtual twins simulate real-world scenarios for planning and testing. Digital twins replicate physical objects for monitoring and analysis.

Conclusion

Digital twins revolutionize industries by offering real-time data and predictive insights. They enhance efficiency and reduce costs. Businesses adopting this technology gain a competitive edge. The future looks promising with continuous advancements. Embrace digital twins to stay ahead in the digital era.

This innovation is key to unlocking new opportunities.