Automation Technology and Engineering focus on using machines and software to perform tasks with minimal human intervention. They enhance efficiency and productivity in various industries.

Automation technology integrates advanced tools and systems to streamline operations. It leverages robotics, AI, and machine learning to optimize processes. Engineers design and implement these systems, ensuring they meet specific industry needs. Automation reduces errors, lowers costs, and speeds up production.

It plays a crucial role in manufacturing, healthcare, and logistics. As technology evolves, the scope of automation expands, offering new opportunities and challenges. Businesses adopting automation can gain a competitive edge. Understanding its principles and applications is essential for staying relevant in today’s fast-paced world.

Credit: essexnorthshore.org

The Rise Of Automation Technology

Automation technology is changing how we live and work. Automation technology improves efficiency and reduces human effort. It has evolved over time and continues to grow.

Historical Evolution

Automation technology has a rich history. Early machines used water power. Steam engines marked a significant advancement. Factories started using machines in the 18th century. The 20th century saw the rise of assembly lines. Computers and electronics advanced automation further. Today, robotics and artificial intelligence lead the way.

Current Trends

Current trends in automation are fascinating. AI and machine learning are major players. These technologies make decisions and learn over time. Robots work in factories, hospitals, and homes. Drones deliver packages and monitor crops. IoT connects devices, sharing data seamlessly.

| Technology | Application |

|---|---|

| AI | Decision making |

| Robots | Manufacturing |

| Drones | Delivery |

| IoT | Data sharing |

Automation technology is growing rapidly. It impacts many industries. Healthcare uses automation for patient care. Agriculture benefits from automated monitoring and irrigation. Transportation sees self-driving cars and smart traffic systems. The future of automation looks promising.

- AI and machine learning

- Robots in various sectors

- Drones for different tasks

- IoT for connected devices

Key Components In Automation Systems

Automation systems rely on several critical components. These components work together to achieve efficient and reliable operations. Understanding these components is essential for anyone interested in automation technology and engineering.

Sensors And Feedback Loops

Sensors are vital in any automation system. They collect data from the environment. This data can include temperature, pressure, motion, and more. Without sensors, systems would lack awareness of their surroundings.

Feedback loops help systems to adjust operations based on sensor data. They ensure that the system operates within desired parameters. Feedback loops can improve accuracy and efficiency.

- Temperature sensors

- Pressure sensors

- Motion sensors

- Proximity sensors

Control Systems And Software

Control systems manage the automation processes. They make decisions based on the input from sensors. Control systems can be simple or complex, depending on the application’s needs.

Software is the brain of the control system. It processes data and makes decisions. Software can be custom-built or off-the-shelf solutions.

| Control System Type | Application |

|---|---|

| Programmable Logic Controllers (PLC) | Industrial automation |

| Distributed Control Systems (DCS) | Large-scale processes |

| Supervisory Control and Data Acquisition (SCADA) | Remote monitoring |

Combining control systems and software creates powerful automation solutions. These solutions are flexible and scalable.

Impacts On Manufacturing Efficiency

Automation technology and engineering are transforming manufacturing. They bring many benefits to the industry. The most notable impact is on manufacturing efficiency. This section explores how automation affects production times and quality control.

Reduced Production Times

Automated systems speed up production processes. Machines work faster than humans. They do not need breaks or rest. This results in reduced production times. Factories can produce more items in less time.

Automation also helps streamline workflows. Robots and machines complete tasks quickly. This reduces bottlenecks in the production line. As a result, products are made faster, boosting overall efficiency.

| Task | Manual Time | Automated Time |

|---|---|---|

| Assembly | 2 hours | 30 minutes |

| Packaging | 1 hour | 15 minutes |

| Quality Check | 3 hours | 45 minutes |

Quality Control Enhancements

Automation also improves quality control. Machines are precise and accurate. They reduce human error. Automated quality checks ensure products meet high standards.

Advanced sensors and cameras detect defects. These technologies identify problems early. This prevents faulty products from reaching customers. Factories maintain high-quality outputs with fewer defects.

- Consistent inspections

- Real-time monitoring

- Immediate feedback

Quality control data is collected automatically. This data helps identify trends and issues. Factories can make informed decisions to improve processes.

Robotics In Engineering

Robotics in engineering is changing the way we work. Robots help in many fields, making tasks faster and easier. They improve safety and efficiency. Let’s explore two exciting areas in robotics: Collaborative Robots (Cobots) and Autonomous Mobile Robots.

Collaborative Robots (cobots)

Collaborative robots, or cobots, work alongside humans. They assist in various tasks, from assembly lines to packaging. Cobots are designed to be safe around people. They have sensors to detect human presence and avoid accidents.

- Easy to Program: Cobots can be programmed with simple instructions.

- Versatile: Cobots can handle different tasks and tools.

- Cost-Effective: They reduce labor costs and increase productivity.

Many industries use cobots for repetitive tasks. They free up humans for more complex work. This partnership boosts overall efficiency and job satisfaction.

Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs) move around without human help. They use sensors and maps to navigate spaces. AMRs are common in warehouses and factories.

| Feature | Benefit |

|---|---|

| Navigation | AMRs move around obstacles smoothly. |

| Flexibility | They adapt to changes in the environment. |

| Efficiency | AMRs work 24/7 without breaks. |

AMRs help in moving goods from one place to another. They reduce the need for human labor in transportation tasks. This leads to faster operations and lower costs.

Both cobots and AMRs are transforming engineering. They bring speed, safety, and efficiency to various tasks. Embracing these technologies will shape the future of work.

Artificial Intelligence And Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming industries. These technologies help automate tasks, improve efficiency, and enhance decision-making. AI and ML are integral to modern automation, driving innovation and growth.

Predictive Maintenance

Predictive maintenance uses AI to predict equipment failures. By analyzing data, AI can foresee issues before they occur. This helps in reducing downtime and saving costs. Companies can maintain their machinery more effectively.

| Benefits | Description |

|---|---|

| Reduced Downtime | Identify issues early and avoid breakdowns. |

| Cost Savings | Lower maintenance costs through timely interventions. |

| Increased Efficiency | Keep machinery running smoothly and efficiently. |

Smart Manufacturing

Smart manufacturing integrates AI and ML to optimize production. It involves using sensors, data analytics, and IoT devices. This leads to more efficient and flexible production processes.

- Real-time Monitoring: Track production lines in real-time.

- Quality Control: Use AI to detect defects early.

- Supply Chain Optimization: Optimize inventory and logistics.

These innovations lead to higher productivity and lower costs. Smart manufacturing is the future of industrial production.

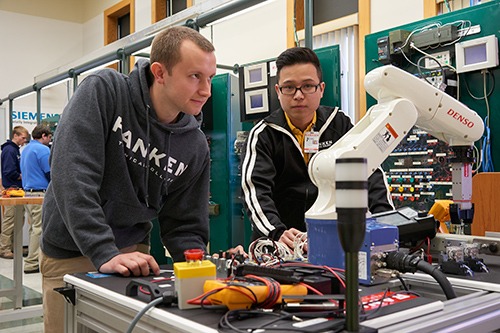

Credit: ranken.edu

Integration Challenges

Automation technology and engineering promise increased efficiency and reduced costs. But integrating these systems comes with its own set of challenges. Understanding these integration challenges is crucial for successful implementation.

Interoperability Issues

One significant challenge in automation technology is interoperability. Different systems and devices often use different protocols. This can lead to communication issues. For instance, a machine using one protocol may not understand another machine using a different protocol. This can cause delays and errors. Ensuring that all systems can communicate is essential.

Here are some common interoperability issues:

- Different communication protocols (e.g., Ethernet, Modbus)

- Proprietary systems that do not share data easily

- Legacy systems that cannot integrate with modern technologies

Cybersecurity Concerns

Cybersecurity is another major challenge in automation technology. Integrating various systems increases the number of entry points for cyber attacks. Protecting these systems is critical to maintaining their integrity.

Consider these cybersecurity concerns:

- Unauthorized access to sensitive data

- Malware attacks that can disrupt operations

- Vulnerabilities in legacy systems

Implementing strong cybersecurity measures is essential. Regularly updating software and using firewalls can help protect these systems.

| Challenge | Impact |

|---|---|

| Interoperability Issues | Communication delays and errors |

| Cybersecurity Concerns | Unauthorized access and malware attacks |

Economic And Workforce Implications

Automation technology is changing the economy and the workforce. It impacts jobs, skills, and industries. Understanding these changes helps us prepare for the future.

Job Displacement And Creation

Automation can displace some jobs. Machines and software can perform repetitive tasks. This reduces the need for certain manual labor jobs.

But automation also creates new jobs. New roles emerge in tech and engineering. For example, there is a growing need for data analysts and AI specialists.

| Job Type | Impact of Automation |

|---|---|

| Manufacturing | Decreased manual labor jobs |

| Tech Industry | Increased demand for AI specialists |

| Data Analysis | Increased demand for data analysts |

Upskilling And Reskilling Initiatives

Upskilling and reskilling are vital in the automation era. Workers need new skills to stay relevant.

Companies invest in training programs. These programs teach employees new technologies and methods.

- Online courses

- Workshops

- Certification programs

These initiatives help workers transition into new roles. They ensure that the workforce adapts to technological changes.

- Identify skill gaps

- Enroll in relevant courses

- Gain certifications

- Apply new skills in the workplace

Upskilling and reskilling benefit both workers and companies. They enhance productivity and job satisfaction.

Future Outlook Of Automation In Engineering

The future of automation in engineering looks promising. Automation technology is evolving rapidly. Engineers are leveraging these advancements for greater efficiency. This evolution is set to revolutionize various industries. Automation will play a crucial role in engineering processes. Let’s explore the exciting future of automation in engineering.

Innovations On The Horizon

Many innovations are on the horizon in automation. Artificial Intelligence (AI) will drive smarter automation systems. Machine Learning (ML) will help in predictive maintenance. Robotics will become more precise and versatile. These technologies will enhance productivity and reduce errors.

Edge computing is another innovation to watch. It allows processing data closer to the source. This reduces latency and improves efficiency. 5G technology will further boost automation capabilities. Faster data transfer will enable real-time automation.

| Technology | Benefits |

|---|---|

| Artificial Intelligence | Smarter systems, reduced errors |

| Machine Learning | Predictive maintenance, efficiency |

| Edge Computing | Reduced latency, better performance |

| 5G Technology | Real-time automation, faster data transfer |

Sustainable And Green Automation

Automation is becoming more sustainable. Green automation focuses on reducing energy consumption. It also aims to minimize waste and lower emissions. Renewable energy sources are being integrated into automation systems. Solar and wind power are popular choices.

Smart grids are an example of green automation. They efficiently manage electricity distribution. Energy-efficient machinery is another focus area. These machines use less power and produce less heat. Sustainable automation also involves recycling and reusing materials.

- Reduced energy consumption

- Lower emissions

- Integration of renewable energy

- Efficient electricity management

- Energy-efficient machinery

- Recycling and reusing materials

Credit: www.linkedin.com

Frequently Asked Questions

What Is Automation Technology?

Automation technology refers to the use of systems to perform tasks without human intervention. It improves efficiency, reduces errors, and saves time.

How Does Engineering Relate To Automation?

Engineering applies principles to design and build automated systems. It ensures these systems are efficient, reliable, and safe for various applications.

What Are The Benefits Of Automation?

Automation increases productivity, reduces costs, and enhances quality. It also minimizes human error and improves safety in hazardous environments.

Can Automation Technology Be Used In Manufacturing?

Yes, automation technology is widely used in manufacturing. It streamlines production processes, boosts efficiency, and ensures consistent product quality.

Conclusion

Automation technology is transforming engineering, increasing efficiency and innovation. Embracing these advancements keeps businesses competitive and forward-thinking. Stay updated to harness the full potential of automation. By integrating cutting-edge tools, engineers can drive progress, enhance productivity, and shape the future of various industries.