Precision engineering focuses on creating highly accurate and detailed components. It plays a crucial role in various industries.

Precision engineering ensures the production of components with extreme accuracy and minimal error. This engineering discipline is vital in fields like aerospace, automotive, and medical devices, where precision is paramount. High-quality materials and advanced technology are essential for maintaining strict tolerances and consistent performance.

Precision engineers often work with computer-aided design (CAD) and computer-aided manufacturing (CAM) software to achieve the desired specifications. By minimizing deviations and enhancing reliability, precision engineering contributes significantly to innovation and technological advancements. This specialized field continuously evolves, integrating new techniques and materials to meet the growing demands of modern industries.

The Essence Of Precision Engineering

Precision engineering is the art of designing machines and structures with exact specifications. It plays a crucial role in many industries. This field demands accuracy and perfection. Precision engineering ensures parts fit together perfectly, reducing errors and increasing efficiency.

Core Principles

The core principles of precision engineering are accuracy, repeatability, and reliability. These principles ensure that each part or product meets exact standards. Accuracy involves creating parts within tight tolerances. This means minimal deviation from the specified dimensions.

Repeatability is producing the same part multiple times with no variation. This is crucial for mass production. Reliability means the parts or systems perform consistently under various conditions.

| Principle | Definition |

|---|---|

| Accuracy | Creating parts within tight tolerances. |

| Repeatability | Producing the same part multiple times without variation. |

| Reliability | Consistent performance under various conditions. |

Impact On Tech Advancements

Precision engineering impacts many technological advancements. It allows for the creation of small, intricate parts. These parts are crucial in modern tech gadgets. Smartphones and computers rely on precision-engineered components for optimal performance.

In the medical field, precision engineering enables the production of accurate surgical instruments. This results in better patient outcomes. Automotive and aerospace industries also benefit from precision engineering. They rely on it for building reliable and efficient vehicles.

- Smartphones

- Computers

- Medical instruments

- Automotive parts

- Aerospace components

Each of these areas requires high levels of accuracy and reliability. Precision engineering makes this possible.

Credit: www.rolandberger.com

Materials Matter: The Building Blocks

In precision engineering, the choice of materials plays a crucial role. The right material can make or break a project. Engineers must consider various factors to ensure optimal performance.

Material Selection Criteria

Engineers use specific criteria to select materials for precision engineering. These include:

- Strength: The material must withstand forces without breaking.

- Durability: It should last long without degrading.

- Weight: Lightweight materials are often preferred.

- Cost: The material should be affordable for the project budget.

- Corrosion Resistance: The material must resist rust and corrosion.

Innovative Materials In Use

Innovative materials are changing the game in precision engineering. Here are some of the latest:

| Material | Properties | Applications |

|---|---|---|

| Titanium Alloys | High strength, low weight, corrosion-resistant | Aerospace, medical devices |

| Carbon Fiber | High strength-to-weight ratio, stiff | Automotive, sports equipment |

| Ceramics | Heat-resistant, hard, brittle | Cutting tools, electronics |

| Graphene | Strong, flexible, conductive | Electronics, sensors |

Precision Techniques: From Theory To Practice

Precision engineering is crucial in modern manufacturing. It transforms theoretical concepts into practical applications. This field ensures high accuracy and quality in product development. Let’s explore some of the latest techniques and their practical applications.

Latest Machining Methods

The latest machining methods in precision engineering are groundbreaking. They include advanced techniques like laser cutting, electrochemical machining, and additive manufacturing.

- Laser Cutting: Uses high-powered lasers to cut materials with extreme precision.

- Electrochemical Machining: Uses electrical energy to remove material and achieve high accuracy.

- Additive Manufacturing: Builds objects layer by layer, allowing for intricate designs and precise details.

These methods offer unparalleled accuracy. They help in creating complex parts efficiently.

Accuracy And Tolerances

Accuracy and tolerances are critical in precision engineering. They define how close the manufactured parts are to their intended design.

In precision engineering, even a tiny error can lead to significant issues. Therefore, maintaining tight tolerances is essential.

| Method | Typical Tolerance |

|---|---|

| Laser Cutting | ±0.005 inches |

| Electrochemical Machining | ±0.001 inches |

| Additive Manufacturing | ±0.020 inches |

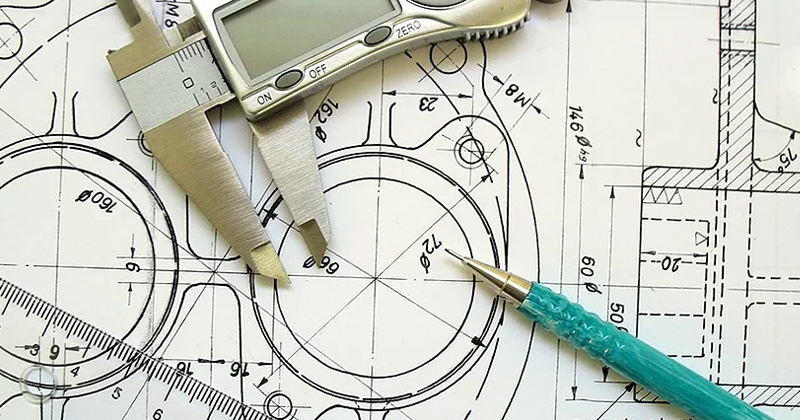

Precision engineers use advanced tools like coordinate measuring machines (CMMs) and laser scanners to ensure parts meet required tolerances. These tools help measure dimensions with high accuracy.

Overall, precision techniques bridge the gap between theoretical designs and practical applications. They ensure products meet the highest standards of quality and accuracy.

Key Tools And Equipment

Precision engineering relies on advanced tools and equipment to ensure accuracy and efficiency. Key tools and equipment play a crucial role in achieving high precision and quality. Let’s explore some of the essential tools and equipment used in precision engineering.

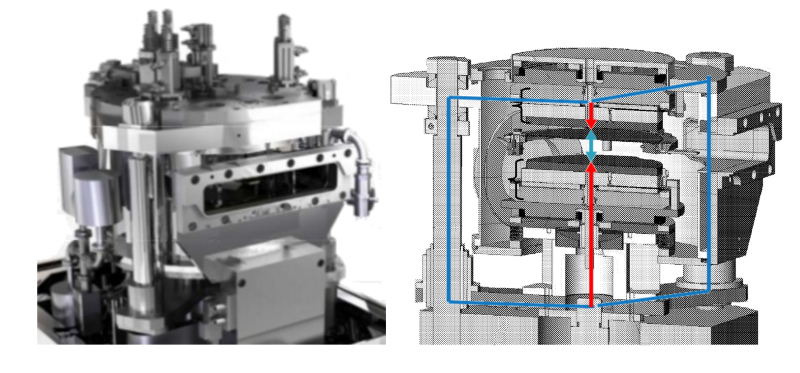

State-of-the-art Machinery

State-of-the-art machinery is vital in precision engineering. These machines offer unmatched accuracy and efficiency. Here are some examples:

- CNC Machines: Computer Numerical Control machines automate machining processes. They ensure consistent precision.

- 3D Printers: These printers create complex parts with high accuracy. They are essential for prototyping and production.

- Laser Cutters: Laser cutters provide precise cutting for various materials. They are ideal for intricate designs.

Measuring And Testing Instruments

Measuring and testing instruments are crucial for maintaining accuracy in precision engineering. These instruments help verify dimensions and tolerances. Some key instruments include:

- Micrometers: These devices measure small distances with high precision. They are essential for checking component dimensions.

- Calipers: Calipers measure both internal and external dimensions. They are versatile and easy to use.

- Coordinate Measuring Machines (CMM): CMMs provide detailed measurements of complex parts. They are crucial for quality control.

- Optical Comparators: These instruments project magnified images of parts. They help in inspecting and comparing components.

Below is a table summarizing the key tools and equipment in precision engineering:

| Tool/Equipment | Function |

|---|---|

| CNC Machines | Automate machining processes with high precision. |

| 3D Printers | Create complex parts with accuracy. |

| Laser Cutters | Provide precise cutting for various materials. |

| Micrometers | Measure small distances with high precision. |

| Calipers | Measure internal and external dimensions. |

| Coordinate Measuring Machines (CMM) | Provide detailed measurements of complex parts. |

| Optical Comparators | Inspect and compare components with magnified images. |

Software In Precision Engineering

Precision engineering relies on software for accuracy and efficiency. It helps design, simulate, and integrate processes. Advanced software tools are indispensable in this field.

Design And Simulation

Design software creates detailed and accurate models. Engineers use these models to visualize products. This software ensures every component fits perfectly.

Simulation software tests the models in virtual environments. Engineers can predict how a product behaves. This helps identify potential issues early.

Both design and simulation software saves time and resources. They reduce the need for physical prototypes. This makes the process faster and more efficient.

Integration With Manufacturing

Software connects design and manufacturing processes. This integration streamlines production. It ensures the final product matches the design.

Manufacturing software controls machinery and tools. It follows the designs created in the software. This leads to precise and accurate production.

Integration software tracks the entire process. It provides real-time data and analytics. Engineers can monitor and adjust as needed.

| Software Type | Function |

|---|---|

| Design Software | Creates detailed models |

| Simulation Software | Tests models virtually |

| Manufacturing Software | Controls machinery |

| Integration Software | Tracks processes |

Software is essential in precision engineering. It enhances design, simulation, and manufacturing. This leads to high-quality and accurate products.

Case Studies: Success Stories

Precision engineering has revolutionized various industries. This section covers remarkable success stories. These case studies highlight the transformative impact of precision engineering.

Medical Device Breakthroughs

In the medical field, precision engineering has led to significant advancements. One notable example is the development of minimally invasive surgical instruments. These instruments allow surgeons to perform complex procedures with greater accuracy and minimal recovery time.

Another breakthrough is in the creation of advanced prosthetics. These devices offer enhanced mobility and better quality of life for amputees. Precision engineering ensures these prosthetics are custom-fitted and highly functional.

The production of high-precision diagnostic tools is also noteworthy. These tools enable early detection of diseases, leading to better patient outcomes.

| Medical Device | Impact |

|---|---|

| Minimally Invasive Instruments | Greater Accuracy, Minimal Recovery Time |

| Advanced Prosthetics | Enhanced Mobility, Better Quality of Life |

| High-Precision Diagnostic Tools | Early Disease Detection, Better Patient Outcomes |

Aerospace Innovations

In aerospace, precision engineering has driven remarkable innovations. One example is the development of lightweight, high-strength materials. These materials improve fuel efficiency and reduce environmental impact.

Precision engineering also plays a crucial role in satellite technology. Satellites require extreme precision in manufacturing to function correctly in space. This technology supports global communications, weather forecasting, and scientific research.

Another significant innovation is the creation of advanced navigation systems. These systems ensure safe and efficient travel for both commercial and military aircraft.

| Aerospace Innovation | Impact |

|---|---|

| Lightweight, High-Strength Materials | Improved Fuel Efficiency, Reduced Environmental Impact |

| Satellite Technology | Supports Global Communications, Weather Forecasting, Scientific Research |

| Advanced Navigation Systems | Safe and Efficient Travel |

Challenges And Solutions

Precision engineering is a complex field. It demands high accuracy and meticulous attention to detail. Engineers face numerous challenges daily. But, there are effective solutions to these issues. Below, we explore some common challenges and how to overcome them.

Overcoming Technical Limitations

Technical limitations can hinder progress in precision engineering. Engineers often deal with tight tolerances and complex geometries. Using advanced software tools helps to model and simulate designs accurately. This reduces errors and enhances precision.

Another solution is to invest in high-quality materials. These materials can withstand stress and maintain their shape. This is crucial for achieving precise measurements. Regular calibration of tools and machines also ensures they perform at their best.

| Challenge | Solution |

|---|---|

| Tight Tolerances | Advanced software tools |

| Complex Geometries | High-quality materials |

| Tool Calibration | Regular maintenance |

Cost Management

Managing costs is a significant challenge in precision engineering. High-precision tools and materials can be expensive. To manage costs, engineers can use lean manufacturing techniques. This approach minimizes waste and maximizes efficiency.

Another way to control costs is through bulk purchasing. Buying materials in large quantities often reduces the price per unit. Additionally, using automated systems can save labor costs and increase production speed.

- Lean manufacturing techniques

- Bulk purchasing

- Automated systems

Credit: practicalprecision.com

Future Horizons: What Lies Ahead

The world of precision engineering is evolving rapidly. The future promises exciting advancements. These advancements will change industries and our daily lives. This section explores what lies ahead.

Emerging Technologies

Emerging technologies are set to transform precision engineering. Some of the key innovations include:

- Artificial Intelligence (AI): AI will enhance design and manufacturing processes.

- Nanotechnology: This will allow for incredibly small and precise components.

- 3D Printing: Advanced 3D printing will enable complex and customized parts.

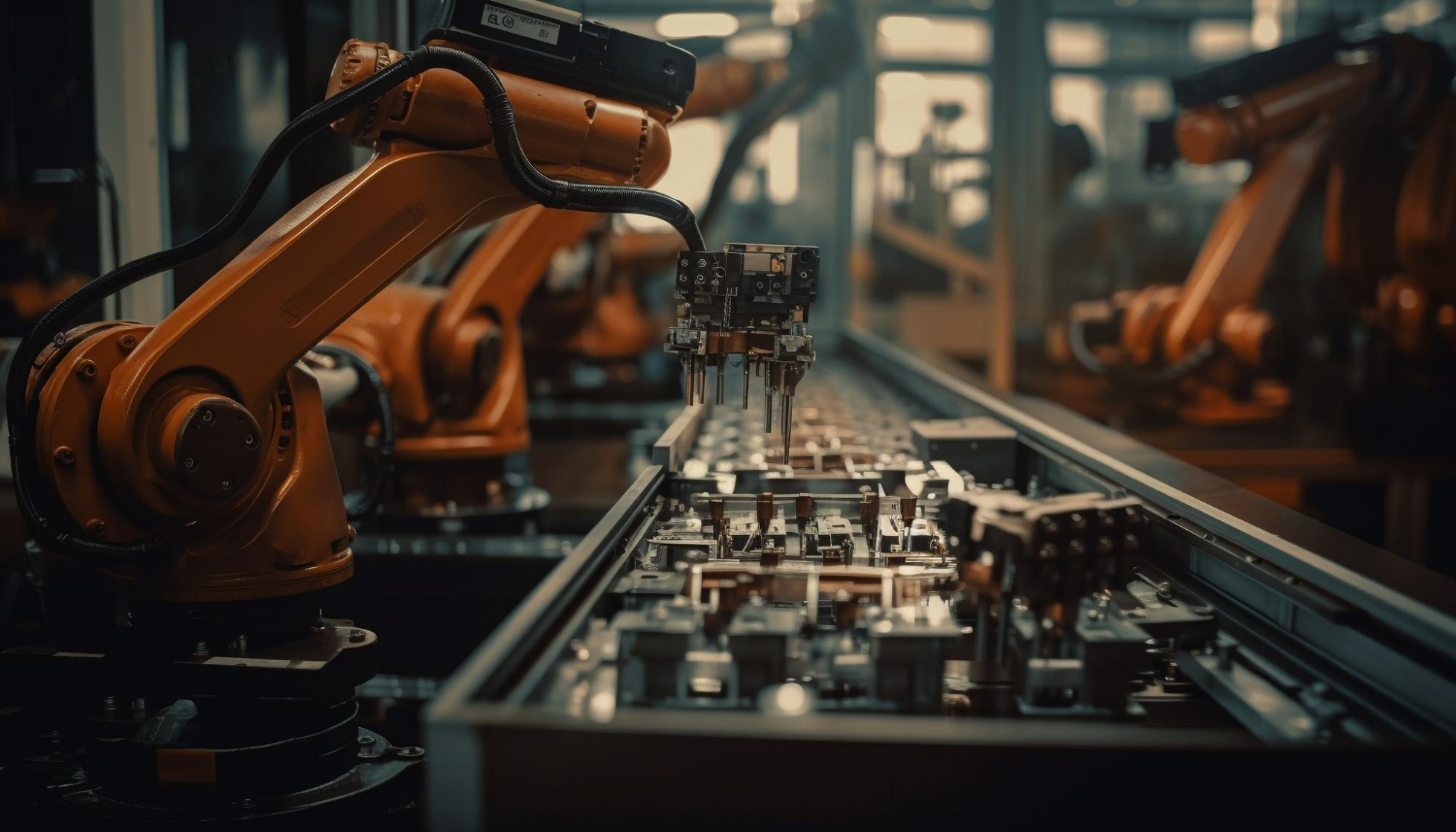

- Robotics: Robots will perform tasks with high precision and efficiency.

Predictions For The Next Decade

The next decade will see remarkable changes in precision engineering. Here are some predictions:

- Increased Automation: More tasks will be automated, reducing human error.

- Greater Accuracy: Precision levels will improve, allowing for finer details.

- Sustainability Focus: Eco-friendly materials and processes will become standard.

- Global Collaboration: Engineers worldwide will work together more closely.

Below is a table summarizing the expected advancements:

| Technology | Impact |

|---|---|

| Artificial Intelligence | Enhanced design and manufacturing |

| Nanotechnology | Smaller, more precise components |

| 3D Printing | Complex, customized parts |

| Robotics | High precision and efficiency |

Precision engineering is on the brink of a revolution. These advancements will bring about incredible changes. Stay tuned for more insights.

Credit: lithub.com

Frequently Asked Questions

What Does A Precision Engineer Do?

A precision engineer designs and manufactures high-accuracy components and systems. They ensure tight tolerances and high-quality standards. They work in various industries like aerospace, medical, and automotive. Their expertise includes CAD software, measurement tools, and material science. Precision engineers optimize manufacturing processes for efficiency and precision.

What Is An Example Of Precision Engineering?

An example of precision engineering is the manufacturing of semiconductor chips. These chips require extreme accuracy and minimal tolerances.

What Is The Precision Engineering Industry?

The precision engineering industry designs and manufactures highly accurate components and systems. It focuses on tight tolerances and fine measurements. This industry serves sectors like aerospace, medical, automotive, and electronics. Its goal is to enhance product performance and reliability through meticulous engineering processes.

What Is The Difference Between Mechanical Engineering And Precision Engineering?

Mechanical engineering focuses on designing, analyzing, and manufacturing mechanical systems. Precision engineering emphasizes creating highly accurate and precise components and instruments.

Conclusion

Precision engineering drives innovation and enhances efficiency across industries. It ensures high-quality, reliable, and durable products. Embracing precision engineering can lead to significant advancements and competitive advantages. Stay ahead by integrating precision techniques into your processes. This commitment to excellence can transform your business and meet evolving industry demands.